Einleitung

Der Umstieg von voluminösen Röhrenmonitoren zu flachen TFTs hat in der Computerwelt zu einer gewissen Spaltung unter den Benutzern geführt. Strom- und platzsparend waren die TFTs zu Anfang in ihrer Darstellungsqualität, was sowohl die Homogenität als auch die Farbdarstellung betrifft, und bei ihren stark eingeschränkten Blickwinkeln CRTs deutlich unterlegen, zugleich haben sich TFTs seit ihrem ersten Erscheinen durch unterschiedliche Latenzen bei den Freunden der Computerspiele und Heimcineasten unbeliebt gemacht. Da seit neuestem auch verstärkt TFT-Monitore und sonstige bildgebende Instrumente in PKWs eingesetzt werden, um z.B. die Sichtweite bei Nacht zu erhöhen und den Fahrer rechtzeitig vor Hindernissen zu warnen, wirken sich die Latenzen des Bildschirmaufbaus auch fern ab vom PC im täglichen Leben aus.

Die Farbdarstellung und Gleichmäßigkeit der Ausleuchtung heutiger qualitativ hochwertiger Geräte sind den besten CRTs bereits überlegen. Doch während die Schaltzeiten der Transistoren, oft als Reaktionszeit in den Datenblättern zu finden, bekannt sind und genormt nach ISO 13406-2 angegeben werden, hinzu auch noch mit vertretbarem Aufwand nachzuprüfen sind, gibt es seit geraumer Zeit einen zusätzlichen Wert, der die Gemüter zunehmend erhitzt. Der sogenannte „Input Lag“.

In diesem Bericht wird das bisherige Testverfahren für den Input Lag genauer untersucht und verbessert, sowie ein alternatives und präziseres Verfahren entwickelt, worauf die Ergebnisse beider Verfahren miteinander verglichen werden. Gegen Ende wird dann versucht, das bisherige Testverfahren und die damit erzielten Ergebnisse zu beurteilen.

Was ist Input Lag?

Als Input Lag wird die zeitliche Differenz aufgefasst, die zwischen der Signalzuspielung zum Monitor vergeht, bis der entsprechende Bildschirminhalt ausgegeben wird.

Verursacht wird diese Differenz durch die im Monitor stattfindende Signalverarbeitung. Hierzu zählen die Interpolation bei der Darstellung von Auflösungen, die von der nativen Auflösung des Monitors abweichen, Overdrive-Verfahren, Kontrast- und sonstige Farbanpassungen, für die z.B. Matrixtransformationen mit endlicher Geschwindigkeit durchgeführt werden müssen. Grundsätzlich können alle Vorgänge, bei denen die dem Monitor zugespielten Bildinformationen im Gerät verarbeitet werden, eine Verzögerung der Bildausgabe bewirken und ihren Beitrag zur gesamten Verzögerung, dem Input Lag, beitragen.

Die Marktrelevanz ist dabei nicht zu verachten, da dieser Wert von vielen Monitorkäufern als der wichtigste Wert angesehen wird, um zu entscheiden, ob sich ein Monitor für Computerspiele eignet. Ein großer Input Lag wird hierbei generell als schlecht angesehen.

Diese Verzögerung addiert sich zu den sonstigen Latenzen, die bei der Bildverarbeitung und -ausgabe auftreten, und führt somit dazu, dass in Situationen, bei denen die Reaktionszeit des Benutzers entscheidend ist, die Informationen leicht verzögert geliefert werden, wodurch ein rechtzeitiges Reagieren erschwert wird. Übertragen auf die Automobilbranche und die Sichtweitenoptimierungen könnte ein träger Monitor die verbleibende Reaktionszeit des Fahrers und somit den verfügbaren Bremsweg verkürzen.

Mit den bisherigen Methoden wurden Input-Lag-Werte von 0 ms bis zu 68 ms ermittelt.

Die Messmethoden und deren Probleme

Vorweg sei gesagt, dass es bisher keine ISO- oder sonstige Norm zur Bestimmung des Input Lags gibt. Kein genormtes und genau definiertes Messverfahren kann also angelegt werden, um vergleichbare Werte zu erzielen und industrieweit oder auch privat angewendet zu werden.

Zurzeit gibt es nur ein weit verbreitetes Verfahren zu Bestimmung des Input Lags, welches sich vermutlich auf Grund seiner niedrigen Kosten durchgesetzt hat. Dieses einfache Verfahren, wir nennen es ab jetzt die „Foto-Methode“, sieht wie folgt aus:

Neben einem CRT wird ein TFT aufgebaut. Beide Monitore werden an einer Grafikkarte angeschlossen und stellen im Clone-Modus, also mit vermeintlich identischen Bildinhalten, bei einer eingestellten Bildwiederholrate von 60 Hz eine Stoppuhr dar. Die Stoppuhr zeigt auf der letzten dargestellten Stelle einzelne Millisekunden an. Durch einfaches Abfotografieren der Monitore und Ermittlung der Differenz der dargestellten Zeiten, wird der Input Lag des TFT-Monitors bestimmt.

Bisher ist keine Quelle bekannt, die die Korrektheit dieses Verfahrens überprüft hat, obwohl die so ermittelten Werte entscheidende Auswirkungen auf die Kaufentscheidung einer breiten Masse haben. Bei diesem Verfahren gibt es eine ganze Reihe an Hürden, die zunächst genau untersucht werden müssen, damit man eine Aussage darüber treffen kann, ob dieses Verfahren sinnvolle Ergebnisse liefert oder nicht.

Ist das Stoppuhrprogramm genau genug?

Im Rahmen der Untersuchungen für diesen Test war es erforderlich, dass eine neue Anwendung programmiert werden musste, die tatsächlich in der Lage ist, eintausend-mal pro Sekunde eine aktualisierte Zeitanzeige zu berechnen und auszugeben. Einige bisher weit verbreitete Stoppuhren basieren auf Flash oder anderen Programmiersprachen, die eine träge 2D-Ausgabe liefern oder sogar zwangsweise an die Bildschirmwiederholrate gebunden sind. Hiermit ergibt sich dann im Idealfall eine Genauigkeit der Zeitausgabe von lediglich 16,67 ms, was der Zeitspanne entspricht, die ein Einzelbild bei 60 Hz Bildschirmwiederholrate angezeigt wird.

Wie groß ist die Latenz eines CRTs?

Bei allen bisherigen Testverfahren wird nicht die Differenz zwischen Signaleingang und Bildausgabe bestimmt, sondern die Differenz zwischen „Bildausgabe des CRTs“ zu „Bildausgabe des TFTs“ gemessen und dies als Latenz des TFTs angegeben.

Eine genaue Betrachtung eines CRTs ist also zunächst nötig, um sicherzustellen, dass tatsächlich keine oder zumindest keine relevante zeitliche Verzögerung der Signalausgabe eines CRTs stattfindet. Dies wird bisher ohne Beweis behauptet und dient zugleich als Grundlage für das gesamte Verfahren.

Sind die Signalausgaben an den Ausgängen einer Grafikkarte synchron?

Bei den bisherigen Begründungen für die Korrektheit der Foto-Methode wird aus der Tatsache, dass bei einer Vertauschung der Grafikkartenausgänge die Ergebnisse „ähnlich“ sind geschlossen, dass kein Fehler in die Messung vorliegt. Es wurde jedoch nie untersucht oder gar bewiesen, ob die Signale gleichzeitig, also synchron, ausgegeben werden.

Hierbei stellt sich natürlich auch die Frage, ob es eventuell sogar Hersteller- oder Modellabhängigkeiten bei den verwendeten Grafikkarten gibt, die die Messwerte beeinträchtigen können.

Wann zählt ein Bildinhalt als angezeigt?

Im Rahmen dieses Tests wird anhand von Messwerten und Beispielbildern illustriert, dass es durch fehlende Normen oder festgelegte Messvorschriften problematisch ist, genau festzustellen, ab welchem Zeitpunkt ein Bild als „komplett dargestellt“ gilt und ob dies der entscheidende Punkt für eine Bewertung darstellt. Es vergeht eine gewisse Zeitspanne, bis ein alter Bildschirminhalt sowohl lokal betrachtet, also in einem einzelnen Bildpunkt, als auch komplett überschrieben wurde. Hier spielt letztendlich auch die Umschaltgeschwindigkeit der einzelnen Transistoren, die Reaktionszeit des im Monitor verbauten Panels, eine Rolle.

Bedienungsfehler der Kamera

Wählt man lange Belichtungszeiten, so dass ein CRT durchgängig erleuchtet erscheint, damit man auch mit lichtschwachen Objektiven noch „freundliche“ und ablesbare Bilder erhält, so kann man häufig keine brauchbaren Werte ablesen.

Der Grund liegt primär darin, dass der Bildaufbau nicht mit der Kamera synchronisiert wird. Idealisiert möchte man eine Momentaufnahme erstellen, die den Stand exakt nach dem Neuaufbau der Stoppuhren auf den Bildschirmen darstellt. Belichtet man nun längere Zeit, so kann es passieren, dass grob zur Hälfte der Belichtungszeit eine oder beide der Stoppuhren durch neue Werte überschrieben werden.

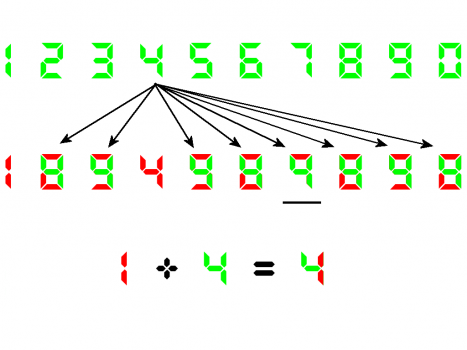

Die Zahlen überlappen sich und werden schwer oder gar nicht mehr ablesbar, im Extremfall sogar verfälscht, wenn sich z.B. bei bestimmten Ziffern und der Darstellungsform einer Siebensegmentanzeige mehrere einzelne Ziffern zu einer anderen ergänzen. Hierfür gibt es eine sehr große Auswahl an Möglichkeiten, die in der folgenden Grafik nur anhand der möglichen Überlagerungen mit der Ziffer 4 demonstriert werden.

Deutlich zu erkennen ist, dass es nur eine einzige Überlagerung mit der Ziffer vier gibt, die keine gültige Zahl darstellt und somit leicht als ungültiger Wert erkannt werden kann. Als Ergebnis treten gehäuft die Werte acht und neun auf, ansonsten ist es bei solchen Fotos teilweise nicht oder zumindest nicht leicht zu erkennen, dass man einer Täuschung zum Opfer gefallen ist.

Zu umgehen ist dieser Effekt nur durch andere Zahldarstellungen und die Anzeige mehrerer Stoppuhren zur gleichen Zeit, anhand derer man den Bildaufbau verfolgen kann.

In diesem Bericht geht es um die Überprüfung, Bewertung und Verbesserung der bisherigen Messmethoden. Hierfür war es somit erforderlich, eine Messmethode zu entwickeln, die den bisherigen Einschränkungen nicht unterliegt, von der verwendeten PC-Hardware unabhängig und reproduzierbar von Dritten durchführbar ist.

Allerdings ist für eine präzise Messung des Input Lags ein erheblicher technischer Aufwand nötig, der es dem Heimanwender praktisch unmöglich macht, die im Laufe dieses Artikels erarbeiteten Ergebnisse zu Hause nachzuprüfen.